value driven export grade finned tube equipment?

Under circumstances elaborate rib tube architecture and fabricating, working with authentic experts is crucial. These competent patterned tube construction masters possess a comprehensive knowledge of thermal conductivity principles, alloy behavior, and the latest strategies for creating superior heat exchangers. They oversee everything from planning and mock-up creation to large-scale production and careful assessment. Electing the right ribbed pipe manufacturing adept can markedly enhance the performance and persistence of your machinery.

Sophisticated Extruded Channels

Modern engineering systems frequently demand distinctly efficient power exchange, and superior finned systems are fundamental to achieving this. These fragments contain specially designed flange geometries, frequently implementing elaborate formulas to improve the stretch available for energy communication. Fabrication systems may feature pressing, preceded by careful fin fabrication and at times a unique surface treatment to extra elevate operation. Adopting the suitable finned duct layout is governed on the specific performance factors, such liquid parameters, heat levels, and strain strengths.

Bespoke Ribbed Alloyed Pipe Designs

Dealing with challenging thermodynamic management necessities? Our expert team crafts bespoke copper line services precisely to your application. We leverage advanced construction techniques and correct calculations to raise power transfer efficiency. Whether you're in the industrial sector, or need effective cooling applying to a advanced facility, our augmented copper pipelines can deliver superior functionality. We evaluate factors such as gas circulation rates, environmental warmth metrics, and geometric constraints for develop a truly bespoke and efficient answer.

Specialists in Aluminum Finned Tube Solutions

For decades, we've been dedicated to providing unparalleled expertise in finned aluminum tube design, manufacturing, and installation. As leading technicians, we offer a comprehensive portfolio of services, catering to a all-encompassing spectrum of industries, including environmental control, energy manufacturing, and chemical engineering. Our workforce of qualified engineers maintains a deep understanding of heat movement principles and constituent science, ensuring that every task we undertake delivers optimal output and lifespan. We pride ourselves on delivering specialized answers that precisely required our clients’ unique requirements. Whether you require radiator repair, refurbishment, or a total system plan, our determination to top-tier standards remains unwavering. Connect with us today to explore your definite complications.

Enhanced Tube Design and Guidance Options

Optimizing caloric dispersion efficiency is paramount in countless applications, and that's where specialized upgraded tube fabrication and advisory provisions truly shine. We deliver comprehensive remedies encompassing everything from initial notion to full-scale implementation. Our workforce of experienced technicians leverage advanced projection techniques and domain best techniques to build customized improved tube configurations for a wide array of complicated environments. Whether you're seeking to maximize operation, lower consumption costs, or tackle specific mechanical problems, our advanced tube expertise delivers best results. We in addition offer periodic support aid to ensure extended productive integrity.

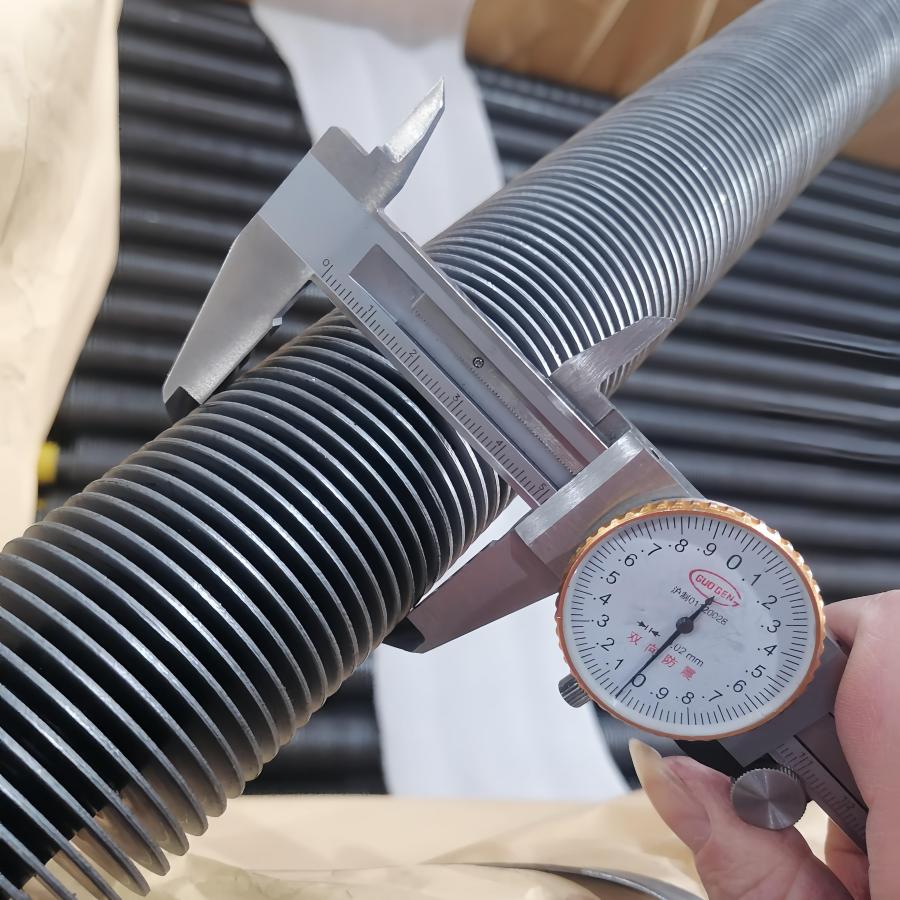

State-of-the-art Precision Extended Tube Manufacturing

The requisitions of modern heat transfer systems are initiating a alteration towards highly precise textured tube fabrication. Traditionally, standard fin forms were acceptable, but now applications in technology and factory processing necessitate remarkably tight tolerances and complicated geometries. This involves faithful forming of fins directly onto the tube shell, often utilizing sophisticated cold manufacturing equipment to gain the desired edge altitude, gap, and configuration. Furthermore, the composition selection plays a key job, with particular metals frequently applied to increase thermal productivity while maintaining structural strength. Grade supervision processes are also indispensable to ensure uniform radiating tube caliber.

Grooved Copper Pipe for Heat Exchangers

Up-to-date heat transfer systems frequently utilize finned copper tubing as a crucial aspect in heat exchangers. The incorporation of fins, commonly made from lightweight alloy, significantly enlarges the surface field available for heat conveyance, leading to a increased efficient heat movement. These augmented copper pipelines are generally found in applications ranging from factory processes, such as thermal management machinery, to family HVAC systems. The astm b171 prime thermal heat transmission of copper, associated with the extended surface area coverage provided by the fins, brings in a profoundly effective method for administering heat. Different fin arrangements, including linear and wavy, present varying degrees of performance improvement depending on the specific application’s needs.

Up-to-date heat transfer systems frequently utilize finned copper tubing as a crucial aspect in heat exchangers. The incorporation of fins, commonly made from lightweight alloy, significantly enlarges the surface field available for heat conveyance, leading to a increased efficient heat movement. These augmented copper pipelines are generally found in applications ranging from factory processes, such as thermal management machinery, to family HVAC systems. The astm b171 prime thermal heat transmission of copper, associated with the extended surface area coverage provided by the fins, brings in a profoundly effective method for administering heat. Different fin arrangements, including linear and wavy, present varying degrees of performance improvement depending on the specific application’s needs.Aluminum Finned Tubes: Lightweight & Efficient

Aluminum enhanced tubes offer a compelling combination of compact construction and remarkable capability, making them ideal for a varied range of manufacturing heat transfer systems. Their unique design—featuring aluminum flanges attached to the tube coat—significantly augments the heat exchange capability without adding substantial volume. This translates to shrunk energy payments and improved overall machinery consistency. Consequently, these tubes are frequently chosen in HVAC apparatus, refrigeration, and other heat convection processes where minimizing load and maximizing heat transfer are paramount concerns.

Fin Tube Component Options: Copper & Aluminium Alloy

At the time when opting for finned tube element, engineers frequently evaluate copper and aluminum. Copper offers exceptional deterioration defense and superior power movement, making it appropriate for applications where efficient heat distribution is paramount, such as in coolers systems. However, copper's elevated cost and anticipated for galvanic corrosion with other elements can be limiting restrictions. Conversely, aluminum provides a significantly lower cost and benefits from a lower density, which is advantageous in weight-sensitive designs. While aluminum's thermal conductivity is lower than copper's, it remains adequate for many applications, and surface treatments can often improve its performance. Ultimately, the best material selection hinges on a thorough analysis of the specific operating conditions, budget constraints, and required performance characteristics.

Boosting Heat Transfer with Finned Sections

The performance of heat apparatus frequently hinges on the design and deployment of finned tubes. These structures significantly enhance the surface area available for heat transfer, allowing for a much greater dispelling of heat compared to simple, unfinned pipes. The boost process involves a complex interplay of factors, including fin shape – such as fin scale, spacing, and gauge – as well as the element of both the fins and the foundation lines themselves. Careful consideration of the fluid flow characteristics, whether it's air or a substance, is also paramount to ensure that the heat removal isn’t restricted by boundary layer effects or uneven allocation of the working mass. Ultimately, a well-designed finned tube array delivers a major improvement in overall thermal operation within a given space.

Resilient Finned Tube Installations for Commercial Applications

Fulfilling the call of demanding production environments necessitates hardy heat transfer mechanisms. Our finned tube ranges are engineered for exceptional efficiency, providing steady heat diffusion in a range of applications, from petroleum processing to air-conditioning control. Constructed from high-end materials and featuring advanced erosion defense techniques, these modules minimize maintenance downtime and maximize operational effectiveness. The tailored fin arrangement promotes improved heat movement, even under tough operating states.